Industry-specific attributes

|

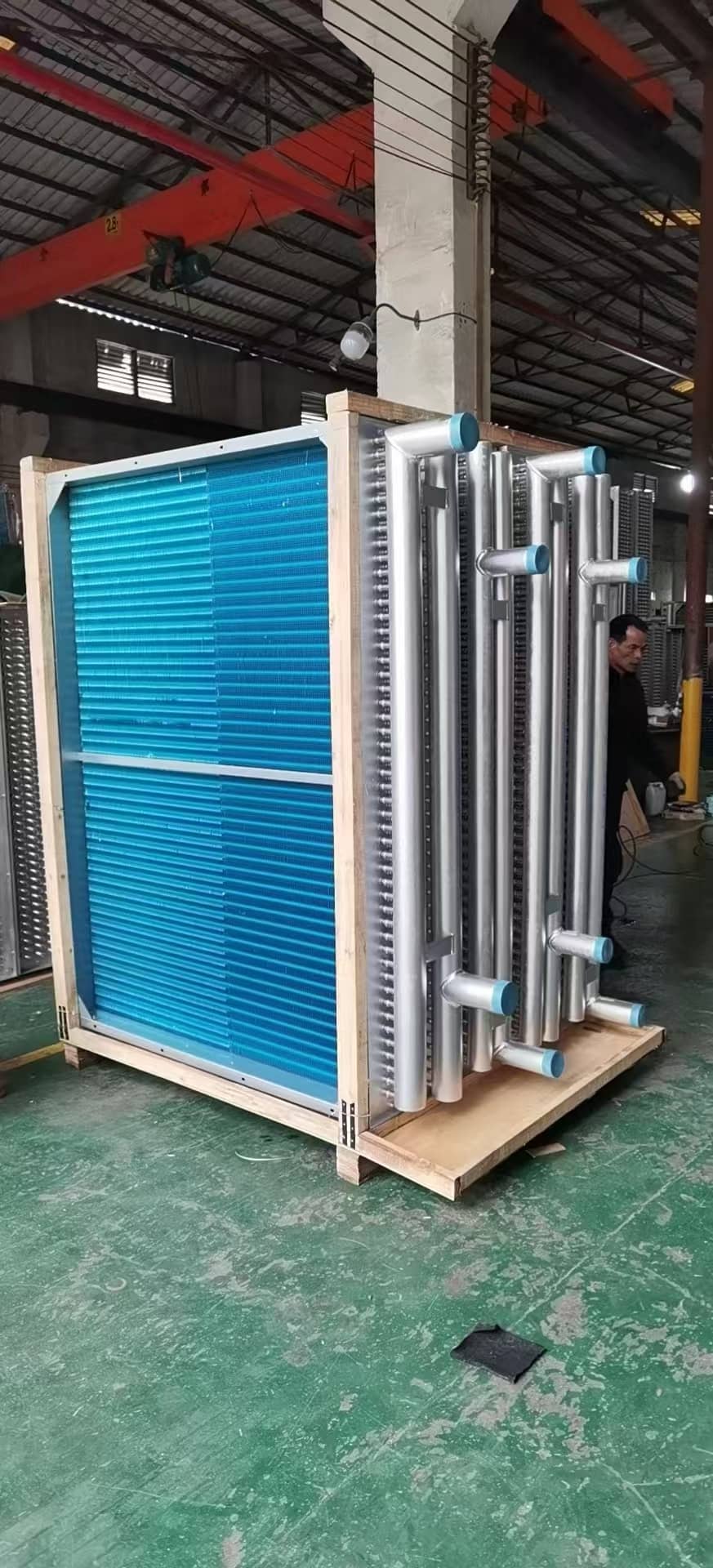

Structure |

condenser coil |

|

Voltage |

220V/380V |

Finned heat exchanger, factory mold specifications

|

Diameter |

Fin spacing |

Hole spacing |

Row spacing |

|

9.52mm |

1.80-6.00mm |

25.00mm |

21.65mm |

|

12.70mm |

1.80-6.50mm |

31.75mm |

27.50mm |

|

15.88mm |

1.80-9.00mm |

38.10mm |

33.00mm |

Other attributes

|

Applicable Industries |

hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Construction works , Energy & Mining, Food & Beverage Shops |

|

Showroom Location |

Foshan China |

|

Video outgoing-inspection |

Provided |

|

Machinery Test Report |

Provided |

|

Warranty of core components |

1 Year |

|

Core Components |

PLC |

|

Place of Origin |

Guangdong, China |

|

Weight |

10 KG |

|

Warranty |

1 Year |

|

Key Selling Points |

leakproof |

|

Condition |

New |

|

Brand Name |

EVER HEAT |

|

Liquid Flow Rate |

2.5m/s |

|

Maximum Working Pressure |

Variable |

|

Dimension(L*W*H) |

Request |

|

Working Temperature Range |

Customize on request |

|

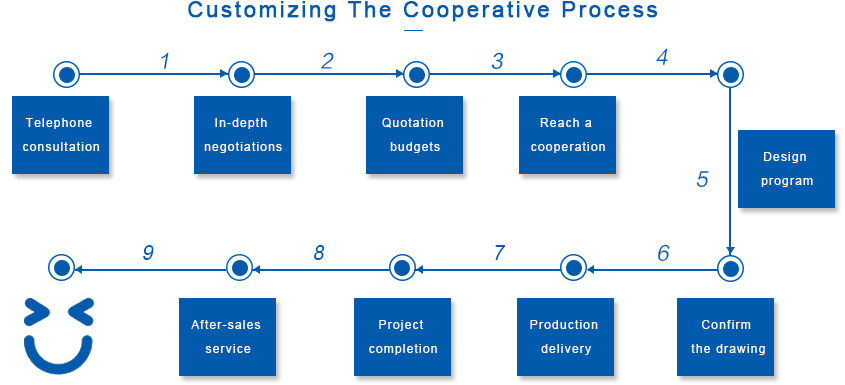

After-sales Service Provided: |

Engineers available to service machinery overseas |

|

Feature |

High energy efficiency-low operating cost, |

|

Type |

Finned tube condenser coil |

|

Material |

All Kind of Material can be applied |

|

Application |

refrigeration condenser |

|

Certification |

TUV, CE |

|

Heat exchanger type |

refrigeration condenser |

|

Whether to accept small orders |

Yes |

|

Function |

Refrigeration Heat Exchange Equipment |