Equipment We Support

EVER HEAT supports a wide range of HVAC & refrigeration systems with high-performance finned heat exchangers.

Discover how our coils enhance efficiency, reliability, and performance across different applications.

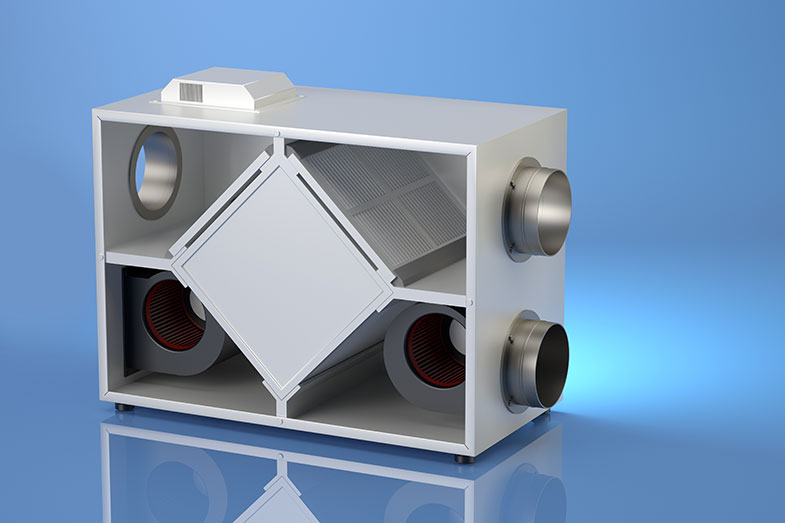

AHU (Air Handling Units)

EVER HEAT finned heat exchangers are used in AHUs for efficient air heating and cooling.

Custom-designed coils ensure optimal air temperature control and energy efficiency in commercial and industrial HVAC systems.

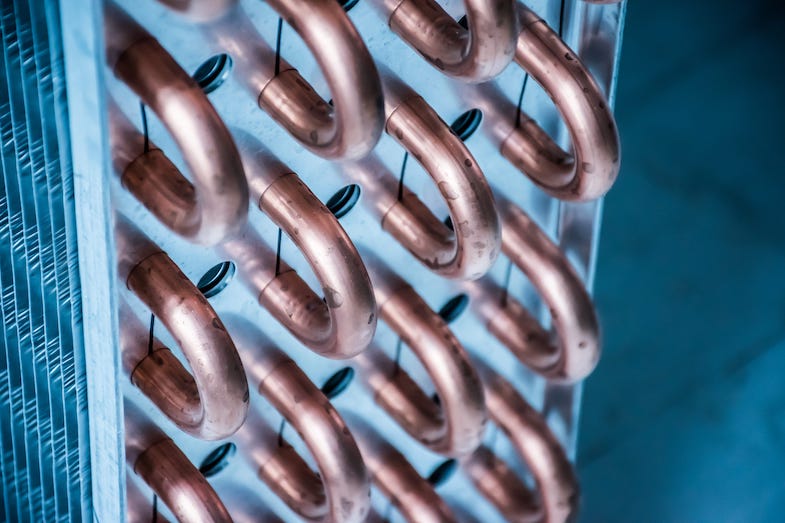

Chillers

Our finned condenser and evaporator coils enhance chiller performance with excellent heat transfer and compact design.

Available in copper or stainless steel tubes with aluminum or copper fins for durability and efficiency.

Dehumidifiers

EVER HEAT coils help improve moisture removal efficiency in dehumidifier systems.

Precision-engineered evaporator coils ensure stable operation and long service life under varying humidity conditions.

Dryers

Used in compressed air dryers and industrial drying systems, our finned evaporator coils enable effective cooling and moisture separation.

High-quality copper or stainless steel tubes ensure reliability and corrosion resistance.

FCU (Fan Coil Units)

Custom finned coils for FCUs provide fast heat exchange and stable indoor comfort.

OEM replacement and custom designs are available for both cooling and heating applications.

Finned Coils / Forced Air Coils

EVER HEAT manufactures high-performance finned coils designed for forced-air systems.

These coils offer excellent heat dissipation, high airflow efficiency, and customizable dimensions to fit your system.

Forced Air Coils

VCOILR (round tube) and VCOILM (microchannel tube) are the REF.BOX module dedicated to the design, virtual prototyping, optimization and commercial characterization of forced air-cooling and air-heating coils such as dry-coolers, air-coolers, remote condensers and gas-coolers, for heat exchanger manufacturers.

Heat Pump Recovery Units

Our finned coils are used in heat recovery and heat pump systems to maximize energy efficiency.

Designed for both heating and cooling cycles, they help reduce energy consumption and operating costs.

Heat Recovery Units

Our finned coils are used in heat recovery and heat pump systems to maximize energy efficiency.

Designed for both heating and cooling cycles, they help reduce energy consumption and operating costs.